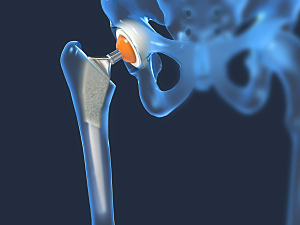

Modular hip prostheses allow implants to be customized to the individual patient’s anatomy via fine-tuning of the femoral offset and leg length, independently of femoral stem size. However, modularity has risks, notably mechanical wear and/or corrosion of the trunnion—the interface between the femoral head and the neck of the femoral stem.

Surgeons at Brigham and Women’s Hospital recently reviewed the causes, treatment, and prevention of mechanically assisted crevice corrosion (MACC, commonly called tunnionosis) in the Journal of the American Academy of Orthopaedic Surgeons. The authors are Vivek M. Shah, MD, director of outpatient arthroplasty in the Department of Orthopaedic Surgery, Daniel M. Estok, II, MD, an orthopedic surgeon in the Department, and Sravya P. Vajapey, MD, MBA, of Rainier Orthopedic Institute.

Modes of MACC

MACC has at least four different causes:

Adverse local tissue reaction (ALTR) is a hypersensitivity reaction of the host to metallic debris released from taper damage. Risk factors include the following:

- Implant-related factors such as high head–neck ratio, dissimilar metal alloy couples, stems with lower flexural rigidity, and implant couples from different manufacturers

- Surgical factors such as lack of proper impaction technique and creating suboptimal loading conditions that require long neck extensions

- Patient-related factors such as high body mass index and increased cyclical loading of the joint

- Dual modularity of the femoral stem

Not all patients with ALTR develop symptoms, but once ALTR is diagnosed, it must be treated by addressing the risk factors and conducting a one-implant or complete revision.

Trunnion fracture is a late-stage complication of taper damage in which mechanically assisted fretting and crevice corrosion lead to gross metallosis and failure of the stem. The risk factors are the same as for ALTR, but femoral stress is the most important contributor to catastrophic trunnion failure. If that occurs, femoral stem revision is required.

Dissociation of the head and neck taper junction can occur spontaneously or because of orthopedic trauma. The underlying cause is taper wear and corrosion, leading to abnormal motion at the head–neck junction.

Taper fit mismatch between the head and the neck can lead to metallosis and fracture or ALTR in metal heads and can be catastrophic in ceramic heads. The effect of taper fit mismatch is multiplied in patients with obesity.

Surgical Pearls

Certain guiding principles can help orthopedic surgeons prolong the survival of hip implants:

- When assembling the head onto the neck, use a concentric and coaxial force ≥6 kN

- Ensure the taper surface is clean at the time of assembly; blood and fat can increase the rate of corrosion

- Carefully consider the pros and cons of a femoral head >36 mm in diameter; a larger head decreases dislocation risk, but when coupled with decreased trunnion size, it increases the risk of fretting wear and subsequent taper damage in certain couples involving cobalt-chromium-molybdenum heads

- When planning to retain the stem during revision, scrutinize the manufacturing tolerances and specifications of the intended head–neck couple and modify the surgical plan accordingly, especially in the case of ceramic heads, as different manufacturers have different machining tolerances

- Recognize that a higher body mass index increases the risk of fatigue failure at the trunnion and constructs with neck extensions; choose constructs that allow favorable biomechanical loading conditions at the modular head–neck junction

The authors present a classification system for grading trunnion damage and an algorithm for deciding whether to explant a femoral stem or retain it after diagnosing MACC.